Guide/Geyser and Vent Taming

Since Geysers are a renewable sources of resources, and putting a structure into place to harness these resources effectively is considered taming the geyser. Some Geysers are more worth taming than others, and some are considerably harder to tame than others yet again. The main goal of any Geyser Tamer is to get as many resources as possible, converting them to a usable form (or temperature), while using as little Steel or Space Age Materials, such as Niobium, Thermium, or Insulation, and as little Power, as possible.

Hydrogen Vent

Hydrogen Vents provide Hydrogen and Heat, both primarily used for Power Generation, and fortunately, it is easy to tame the Vent.

The first step to take, as with any Geyser, is to ensure that it does not reach its PMAX. That's point at which it over-pressurizes, and no longer yields any more Hydrogen. An unpowered Guide/Door Pump can easily transport the Hydrogen Gas away from the Vent and into a pressure chamber in which the Hydrogen can collect.

Next, or simultaneously, the Hydrogen needs to reach a cold enough point at which it can be handled with Steel Equipment. If both the Vent and pressure chamber are connected to a steam room, which in turn is cooled by a Steam Turbine, the Hydrogen's Temperature will easily drop down to 125°C.

Even if the Hydrogen Vent yields ~700g/s while active, this is only (700x2.4x375) 630kDTU/s, and approximately a third to half of that averaged out over its active period.

A Steam Turbine deletes about 250kDTU/s when working with 125°C Steam, and 334kDTU/s when working with 135°C (the approximate Temperature at which Steam Turbines can still cool themselves down). Since enough space is given, two Steam Turbines will easily manage the heat off the Vent.

Now the Hydrogen Gas needs to be distributed to Hydrogen Generators. To cool the Hydrogen down one last time one may want to snake it through the steam chamber before exiting to a Power Plant. Since Gold Amalgam Hydrogen Generators and Power Transformers, and Gold Smart Batteries have a maximum operating Temperature of 125°C, we still need to cool the environment down, if ever so slightly, to... say 115°C.

200g of Hydrogen from 125°C to 115°C hold 4.8kDTU, 2 Hydrogen Generators generate 4kDTU each, 4 Smart Batteries generate 500DTU each, and the Power Transformer generates 1kDTU; for a total of 15.8kDTU that need to be removed. This can easily be moved by a Thermo Regulator which can be placed in the Steam Room with which we cool the Hydrogen initially.

For larger Hydrogen Generator Arrays, a Thermo Aquatuner is recommended as it can move more heat per second and moves more DTU per Watt used.

Metal Volcanos

Copper and Gold comes out HOT, 2226.85°C and 2626.85°C respectively, and they need to be cooled down to 275°C to not destroy our Steel Equipment.

| Material | DeltaT | SHC | DTU per gram |

|---|---|---|---|

| 2351.85 K | 0.129 | 303.39DTU/g | |

| 1145.00 K | 0.386 | 752.61DTU/g | |

| 806.85 K | 0.385 | ||

| 1145.00 K | 0.449 | 1055.98DTU/g |

If cooled by its own output, the Maximum Cooling we can allow a Steam Turbine to do, is to cool down 135°C Steam to 95°C Water, or 37.43kDTU/s. If we subtract a tenth of which and its own heat production of 4kDTU, its net heat deletion is 296,888 DTU/s.

With this we can calculate how much a Metal Volcano is allowed to yield.

However, the average yield cannot be taken, since the heat comes in spikes, therefore we need to use the average during its Eruption Cycle, not over its lifetime Example: 9.9kg/s for 53s over 913s are 574.7g/s (Average yield over eruption cycle range from about 400g/s to 700g/s (needs confirmation))

However, this still may not hold true if a Volcano yields 17.5kg/s for 20 seconds per 900seconds (583.33g/s), since heat that is this rapidly introduced.

With the facts above combined it is not feasible to have a one-size-fits-all-solution, rather two tiers with optional cooling each. Gold and Copper Volcanoes fall into Tier 1 indiscriminately, and Iron Volcanoes are split up. Those Iron Volcanoes with average yield above 500g/s (over active period) or 150g/s (over lifetime) fall into Tier 2. In addition, those Volcanoes with yield above 10kg/s (in activity) should be equipped with optional cooling. Cooling that should only be active if the Steam directly underneath the Steam Turbines rises above 135°C, AND the cooling loop rises above 95°C.

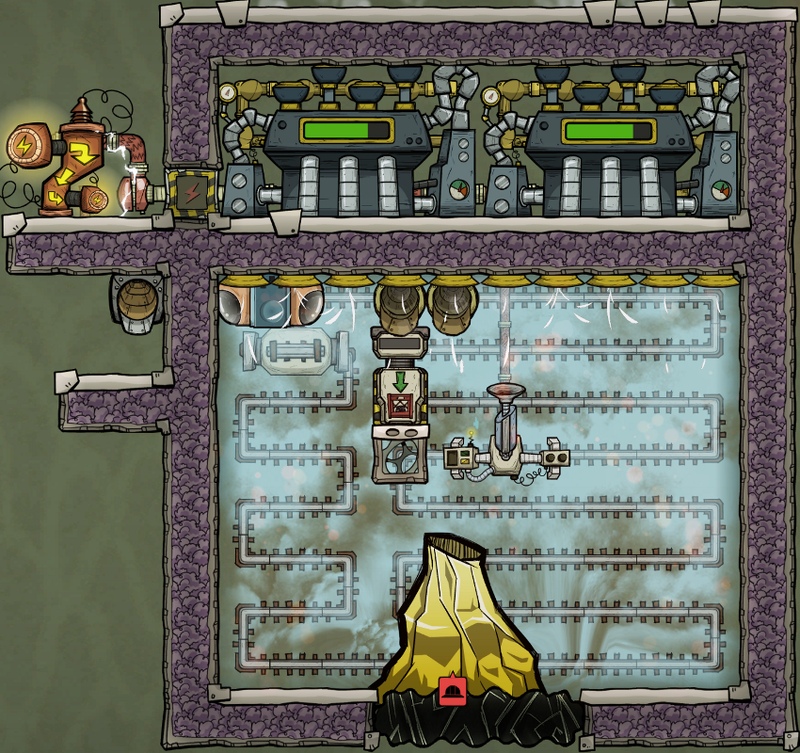

Tier 1

Tier 1 with cooling

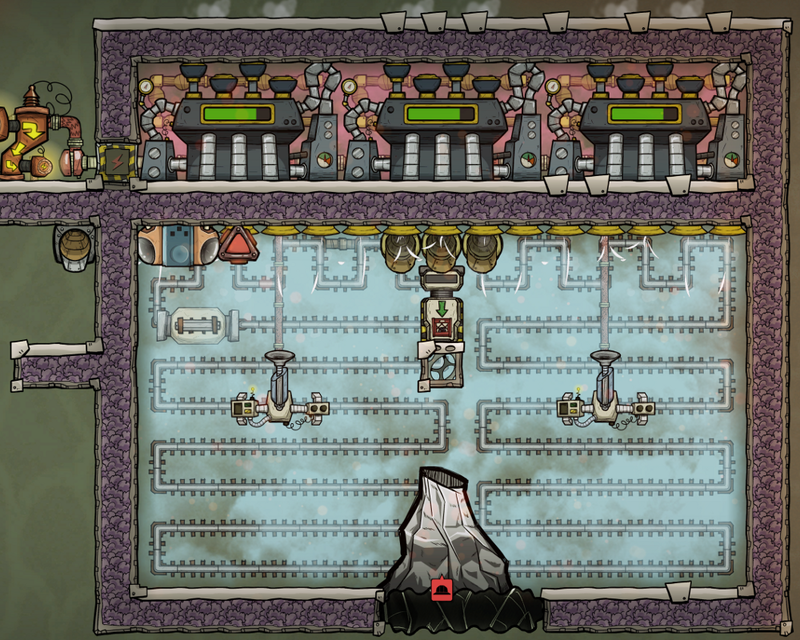

Tier 2

Tier 2 with cooling

Natural Gas Vent

Natural Gas's only uses are to create Power, and supply the gas range. The first few steps are very similar to the first steps for the Hydrogen Vent (see above). Since the Natural Gas comes out at 150°C, one can reason that it's almost not worth initially cooling it down to 125°C, but the Steam room will be needed to cool the Natural Gas Generator setup. Cooling 70 to 140 g of Natural Gas by 25°C, with Natural Gas' considerable SHC of 2.191, is 3.8 kDTU to 7.7 kDTU that does not need to be cooled later (equating to roughly 7.86 W to 15.73 W)

As opposed to Hydrogen Vent Taming, the Natural Gas Generators have waste products in the form of CO2 and Polluted Water.

The CO2 can be Vented out into space, or be put into its own pressure chamber where it can be forgotten about without a pipe running through the entire base.

Tidy people can also run them through a Carbon Skimmer, which would double the amount of sand needed when Sieved, add 4.06W to 8.12W, and 68.83 DTU to 137.67 DTU.

Either way 70g to 140g Natural Gas yield 622.22W to 1244.44W, also yield 58.33g to 116.67g clean water. Electrolyzed, this yields 6.53 to 13.07 g Hydrogen for an additional 52,27W to 104.53 W. Taking Gas Pumps in the ideal situation into account, this would yield 604.63 W to 1209.26 W, and adding 3 smart batteries and one power transformer produces 10,392.69 DTU to 18,285.39 DTU. (or, for those who skimmed their CO2, 600.57 W to 121.14 W and 10,461 DTU to 18423.06 DTU)

Cooling should go to just below Water's boiling point, as such most heat mass will be removed when going into an electrolyzer, but some buffer should exist. As operating Temperature we should use 95°C. Our two inputs are the 70g to 140g Natural Gas and from 125°C for 4601.1 DTU to 9202.2 DTU, and 10.5 g to 21 g Regolith from 125°C (also lead through the Steam room first) for 63 DTU to 126 DTU. (or, for those who skimmed their CO2, 22.17g to 44.33g for 133 DTU to 266 DTU)

In total these are 15.06kDTU to 27.61kDTU, or if carbon skimmed, 15.2kDTU to 27.89kDTU.

For a larger scale operation that produces power on demand with 11 Natural Gas Generators running at once, with 11 Smart Batteries, Heat production can spike up to 184.09kDTU (or 186.05 kDTU if skimmed). Fortunately, only a single piece of additional equipment would need to be installed to keep up with the emergence of more by-products, a second Gas Pump for the Oxygen produced.

Steam Vent Taming

Preface: Why?

Let’s pose the stupid question first: can we not just slap a Steam Turbine on it? Is that not what they were literally made for? There are two main reasons.

First: Steam Turbines produce the most amount of power at a Steam Temperature of 200°C, that means the same amount of power is produced if the Steam is 500°C. That is 300 Degrees of wasted potential.

Second, and more importantly: Steam Turbines produce 4,000 DTU/s plus 10% of the heat they destroyed from the water. For 500°C Steam to 95°C Water (SHC: 4.179) at a rate of 2kg/s, that’s an astonishing 3,384,990 DTU/s, or what ~5.8 Thermo Aquatuners primed with Polluted Water can handle and which cost ~6960 W to cool, only to gain 850 W and 2kg of 95°C Water per second.

But this is still not the only problem with Steam Vents. Since they over-pressurize at 5kg, and some very much able to spew forth more than 5kg/s the Steam needs to be removed as fast as possible to make the most of what it provides. Water and Power.

Useful Trivia

One may think that reintroducing water into the steam chamber will cool the steam down and therefore yield less power, but Steam Turbines yield their power proportional to the amount of heat they delete according to following formula:

85/21 times 2kg/s times the difference in temperature between the steam and the eventual output 95°C

First, lets assume we have 10kg Steam at 200°C, for 5 seconds it will provide 850 W → a total of 8358000kDTU deleted for 4250 J

Then, lets assume the same 10kg of Steam at 200°C but add the 95°C Water back in instantaneously and lets assume the Steam Turbine could suck up water 95°C hot. For the first second we get 850W. The second second the steam will be 179°C for 680W, the third second 162.2°C for 544 W... On an infinite timescale the water will have reached 95°C a total of 8358000kDTU deleted for 4250 J.

Of course a steam turbine will stop at 125°C, but the DTUs remain to be harnessed later.

As a matter of fact the opposite holds true since the more important limit is the 200°C maximum Temperature, or rather the 850W power cap.

If we run the same thought experiment as before, 10kg of Steam at 300°C will still run for 5 seconds at 850 W and produce 4250J of power... however, the cooled Steam can run for 9 seconds at ever decreasing Wattage (see table below), but produce 5684.69 Joule while doing so.

| Steam temp |

temp difference |

Power produced | |

|---|---|---|---|

| 1 | 300,00 °C | 205,00 | 850,00 W |

| 2 | 259,00 °C | 164,00 | 850,00 W |

| 3 | 226,20 °C | 131,20 | 850,00 W |

| 4 | 199,96 °C | 104,96 | 849,68 W |

| 5 | 178,97 °C | 83,97 | 679,74 W |

| 6 | 162,17 °C | 67,17 | 543,79 W |

| 7 | 148,74 °C | 53,74 W | 435,03 |

| 8 | 137,99 °C | 42,99 | 348,03 W |

| 9 | 129,39 °C | 34,39 | 278,42 W |

| 10 | 122,51 °C | temp too low | |

Therefore we should always try to reintroduce water to keep the temperature of the steam between 125°C and 200°C

The Design

under construction

other Geysers

under construction